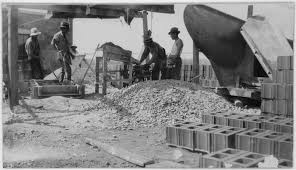

Ready mix concrete (RMC) is a ready-to-use material, with a pre-determined mixture of cement, sand, aggregates and water. RMC is a type of concrete manufactured in a factory according to a set recipe or as per specifications of the customer, at a centrally located batching plant.

Most of the ready mixed concrete is currently manufactured under computer-controlled operations and transported and placed at project sites using sophisticated equipment and methods. RMC is delivered to a worksite, often in truck mixers capable of mixing the ingredients of the concrete on route or just before delivery of the batch.

Read here about What is concrete and construction?

Similarly, most of the ready mixed concrete is currently manufactured under computer-controlled operations and transported and placed at project sites using sophisticated equipment and methods. Ready mix is delivered to a worksite, often in truck mixers capable of mixing the ingredients of the concrete on route or just before delivery of the batch.

History

- In 1903, Ready Mix Concrete (RMC) was first patented in Germany

- In 1913, the first delivery of RMC was made in BALTIMORE

- In 1926, production of first transit mixer for delivering the concrete

- In 1931, RMC plant was set up for the construction of Heathrow airport, London

- In Mid-1990, there were about 1100 RMC plants in United Kingdom

Advantages Of Ready Mix Concrete (RMC)

- Production of concrete in better quality and quantity.

- Elimination of storage space for basic materials at the site.

- Elimination of Hiring plant and machinery

- To avoid wastage of basic materials

- They will eliminate labors for production of concrete.

- It reduces the required time of work.

- It reduces the noise and dust pollution on site.

- There is no wastage on site.

- It is environment friendly.

Limitation Of Ready Mix Concrete (RMC)

- Need a huge initial investment.

- Not affordable for small projects (a small quantity of concrete)

- Needs an effective transportation system from RMC to site.

- They should provide admixture properly otherwise there is traffic jam or failure of the vehicles will create difficulty.

- Labors should be available and active on-site because the concrete in position to vibrate it and compact it.

- Concrete’s limited time between mixing and going-off means that ready-mix should be placed within 90 minutes of batching at the plant.

Scope Of Ready Mix Concrete

- Major concerting projects like dams, roads, bridges, tunnels, canals etc.

- For concreting in clogged areas where the storage of materials is not possible.

- Sites where the intensity of traffic causes problems.

- There is less supervisor and labor staff

- It can reduce the time required for construction etc.

- Huge industrial and residential projects.

Ready Mix Concrete is a modernized technique of production of concrete in huge quantities away from the actual site of place. And to make it is very beneficial because the demand for concrete is very high and construction sites are in congested areas. Like, where mixing on site is not possible due to lack of storage place. RMC is ready to use the material.

RMC is widely utilized throughout the world and gives higher strength to the structure and it also provides higher durability to the structure. It reduces noise pollution as well as air pollution. The supervisory and labor costs associated with the production of concrete is less, and the quality of concrete is high.

In addition, It is suitable for huge industrial and residential projects because time plays an important role. So ultimately it provides economy in the construction and however better finish to the structure. Therefore in conclusion, the advantages of RMC are apprehended by engineers and contractors in the construction industry.